Star Tecnologia

A STAR TECNOLOGIA – Desde 1999 atendendo os Fabricantes de Tubos e Perfis bem como Centros de Serviços especializados em processamento de bobinas de aço carbono,inox e alumínio, proporcionando soluções técnicas e operacionais na fabricação de seus produtos com a qualidade adequada às suas aplicações.

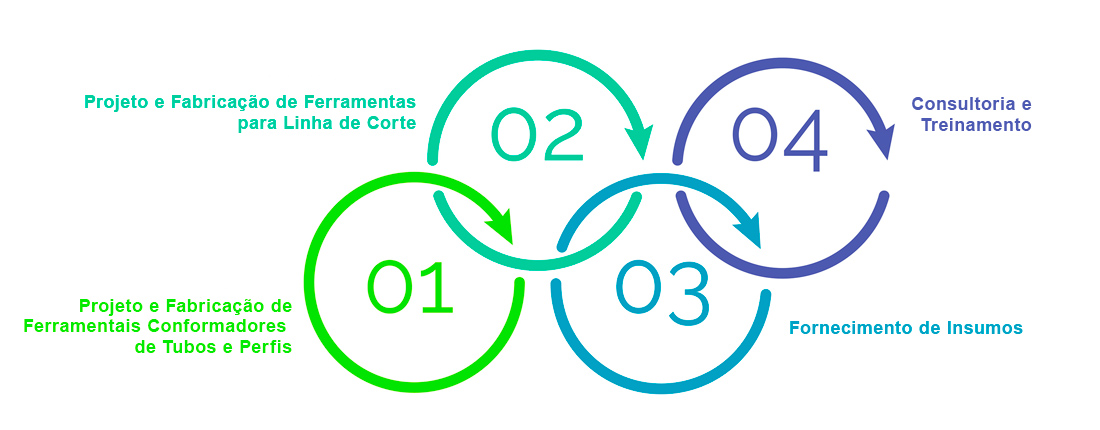

A STAR TECNOLOGIA atua e controla em todas as etapas do seu produto e processo: